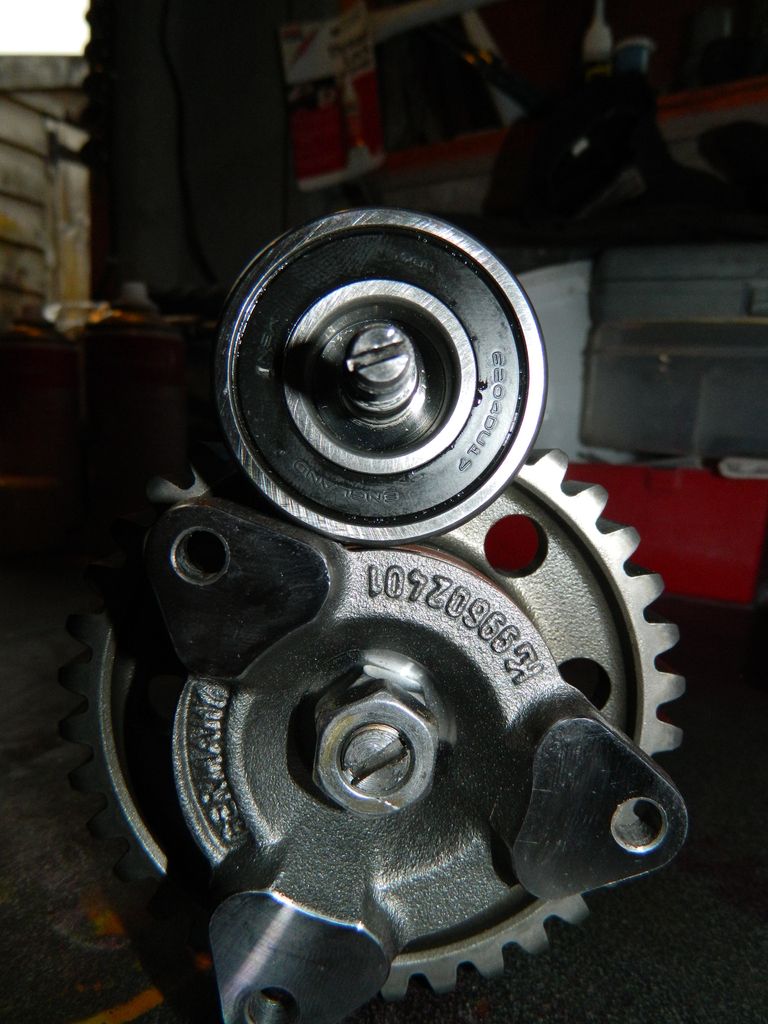

poppopbangbang said:I've had a look at mine today. Dual row, 1999 MY C4 with just shy of 300K miles on it. I was planning to change it but there is no point. The oil seal wasn't much of a seal anymore so it's been fed engine oil for who knows how long anyway.

The dual row bearings have nearly twice the load capacity of the single row bearing and in reality don't fail unless you are really, really unlucky. I think the failure rate is something like 0.6% for dual row at 100K miles vs 8% for single row.

Steel ball bearings operating within their load rating either fail in very short order or run forever.... unless they are ceramic bearings, I've used ceramic silicon nitride and zirconia based ceramic bearings in motorsport applications (e.g. clutch basket bearings on gearbox front covers) and whilst they offer advantages in weight and friction they are not stronger than steel bearings despite what people think (hardness is not strength) and are prone to developing play from the ultra hard ceramics running against the steel race if the lubrication supply is not controlled accurately. In an application like the IMS bearing play becomes failure quite quickly. To give an example we used to life the ceramic bearings carrying the clutch basket in one of our F1s at 500KM, these days we use steel in the same application and the oldest has 2200KM on it and is still going strong.

My vote if it's a dual row just leave it alone.

Why would Porsche have moved from the dual row bearing with twice the load capacity to a single row with, by extension, half the load capacity? What precipitated that change or necessitated it?