Porsche 911 UK Enthusiasts Online Community Discussion Forum GB

Welcome to the @Porsche911UK website. Register a free account today to become a member! Sign up is quick and easy, then you can view, participate in topics and posts across the site that covers all things Porsche.

Already registered and looking to recovery your account, select 'login in' and then the 'forget your password' option.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

996 neglected, time for some love & maintenance

- Thread starter infrasilver

- Start date

MisterCorn

Fuji

- Joined

- 8 Jan 2011

- Messages

- 9,410

Dammit said:I was going to replace my expansion tank whilst the engine was out- until I saw it was ~£400, then I decided to replace it at another point.

Yes, If you have a 3.4 then the prices are horrific, not so bad for the 3.6. I had to do the one on my 3.4 recently but was lucky to source an unused secondhand one for much more reasonable money. I recently changed one on a 1989 Mercedes of mine, £18 for a genuine one from Mercedes.

It isn't that hard to do with the engine in, you just need to drop it a little bit.

MC

infrasilver

Moderator

- Joined

- 4 Oct 2010

- Messages

- 9,933

I've found a used 2006 header tank on ebay for a reasonable price so will be fitting this in a couple of days when it turns up. New ones are around £180 and ECP seem to do one at around £80 but I was unsure if that was a pattern part or not so I went with a good used one in the end.

I've split the gearbox from the engine and have greased the clutch release fork arm a little where the slave cylinder goes so I hope this stops the creaking noise. I have also fitted the new release bearing, the old one was quite wobbly so I hope this to cure the other noise that was annoying me.

I'm happy to say I have no misting from either the RMS or IMSB seal.

The oil misting from around the AOS is worse than I thought and there are small puddles of oil on top of the crankcase fins, this must have been collecting for a while as it's like treacle. I'm still not 100% where this is coming from still but I wouldn't have been able to see this with the engine in situ.

I'll be able to see a little better once I drag the engine from under the car, the AOS is a job for Thursday and will take a bit of cleaning up in this area.

I may have also found why my AC keeps losing gas, the green O ring going onto the compressor has been crushed somewhat, there was no dye to be seen in this area but fingers crossed this is the reason.

One reason I like to do my own work, I can do other small preventative jobs that no paid mechanic would do and I cleaned up the oil pressure sender connections as they were starting to look a little corroded.

I have sent the CAT away to get the other Oxygen sensor out and chase the thread on the one I got out, should get this back on Thursday afternoon.

I've split the gearbox from the engine and have greased the clutch release fork arm a little where the slave cylinder goes so I hope this stops the creaking noise. I have also fitted the new release bearing, the old one was quite wobbly so I hope this to cure the other noise that was annoying me.

I'm happy to say I have no misting from either the RMS or IMSB seal.

The oil misting from around the AOS is worse than I thought and there are small puddles of oil on top of the crankcase fins, this must have been collecting for a while as it's like treacle. I'm still not 100% where this is coming from still but I wouldn't have been able to see this with the engine in situ.

I'll be able to see a little better once I drag the engine from under the car, the AOS is a job for Thursday and will take a bit of cleaning up in this area.

I may have also found why my AC keeps losing gas, the green O ring going onto the compressor has been crushed somewhat, there was no dye to be seen in this area but fingers crossed this is the reason.

One reason I like to do my own work, I can do other small preventative jobs that no paid mechanic would do and I cleaned up the oil pressure sender connections as they were starting to look a little corroded.

I have sent the CAT away to get the other Oxygen sensor out and chase the thread on the one I got out, should get this back on Thursday afternoon.

infrasilver

Moderator

- Joined

- 4 Oct 2010

- Messages

- 9,933

alex yates said:What date's this year's tour?

Hats off to you Chris but you do like to cut things fine.

Got 17 days to go yet, there isn't a massive amount to do in reality but yes I do seem to like a race against time.

Chris

Good work, are you going to pressure clean off the top of the motor?

Looks like its oil wet on the RHS too in the pic of the oil pressure sender, anything leaking that side?

I noticed your fuel rails are looking quite corroded, have a good look to make sure it's nothing too deep. You could probably whip them off and clean and paint them and If you want to do this I recommend replacing the fuel injector seals, let me know if you want a set and send you some.

:thumb:

Good work, are you going to pressure clean off the top of the motor?

Looks like its oil wet on the RHS too in the pic of the oil pressure sender, anything leaking that side?

I noticed your fuel rails are looking quite corroded, have a good look to make sure it's nothing too deep. You could probably whip them off and clean and paint them and If you want to do this I recommend replacing the fuel injector seals, let me know if you want a set and send you some.

:thumb:

infrasilver

Moderator

- Joined

- 4 Oct 2010

- Messages

- 9,933

Your eagle eyes have noticed the fuel rails too, I have planned to refurb these a little and use some of the same rust paint I will be using on the underside cross braces that have surface rust. There are also a couple of seams I have noticed that need a little cleaning up and protection on the bulkhead that you can't see with the engine in place.

I have cleaned some of the engine so far with brake cleaner as this stuff shifts oil build up like nothing else but ideally I will need to get the engine on a trolley to get it somewhere outside so I can give it a blast with the pressure washer or it'll cost about £2k in brake cleaner to clean it all up.

I didn't get chance to strip the AOS off today so hopefully I will have an answer tomorrow. There is also a chance that the O rings on the plastic pipe, you are taking about, could be leaking.

I have cleaned some of the engine so far with brake cleaner as this stuff shifts oil build up like nothing else but ideally I will need to get the engine on a trolley to get it somewhere outside so I can give it a blast with the pressure washer or it'll cost about £2k in brake cleaner to clean it all up.

I didn't get chance to strip the AOS off today so hopefully I will have an answer tomorrow. There is also a chance that the O rings on the plastic pipe, you are taking about, could be leaking.

infrasilver

Moderator

- Joined

- 4 Oct 2010

- Messages

- 9,933

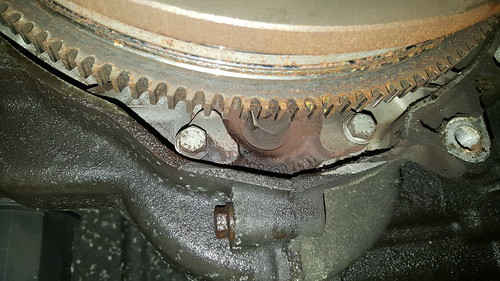

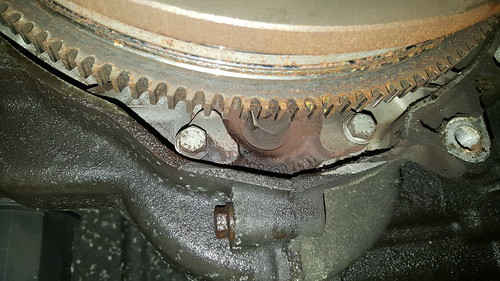

Oh yeah, I forgot to post this pic,

the hope that the bellhousing bolt that snapped off would be sticking out a little to allow me to weld a nut on didn't materialise, it snapped off about 5mm deep into the bolt hole and I can't exactly get the engine anywhere to get it removed. :x :x :x :x :x :x :x :x :x :x :x :x :x :x :x :x :x :x :x :x :x :x :x :x :x :x :x :x :x :x :x :x :x :x

the hope that the bellhousing bolt that snapped off would be sticking out a little to allow me to weld a nut on didn't materialise, it snapped off about 5mm deep into the bolt hole and I can't exactly get the engine anywhere to get it removed. :x :x :x :x :x :x :x :x :x :x :x :x :x :x :x :x :x :x :x :x :x :x :x :x :x :x :x :x :x :x :x :x :x :x

I saw Pelican parts recommend replacing the release lever and ball pin, and the release bearing guide tube to eliminate any creaks, and sell a super kit with everything:

http://www.pelicanparts.com/catalog/SuperCat/996J/POR_996J_TCLUTC_pg1.htm

Dunno but it was on my mind to change those when I do my clutch.

http://www.pelicanparts.com/catalog/SuperCat/996J/POR_996J_TCLUTC_pg1.htm

Dunno but it was on my mind to change those when I do my clutch.

Hi Infra,

Don't be afraid to drill and re-tap. Go very carefully, start with 2.5 or 3mm max, center punch and continually check for being centered at the beginning of the pilot hole (first drill). If you wander off at the beginning you can angle the drill to "steer" the hole into the proper position shortly after starting. Once you get close, the tap will actually clean the original threads rather than cutting new threads if all is good.

Don't recall ever having done bell housing bolts/studs, but I can't recall how many exhaust studs I've drilled out. Not rocket science - just diligence.

:thumb:

Don't be afraid to drill and re-tap. Go very carefully, start with 2.5 or 3mm max, center punch and continually check for being centered at the beginning of the pilot hole (first drill). If you wander off at the beginning you can angle the drill to "steer" the hole into the proper position shortly after starting. Once you get close, the tap will actually clean the original threads rather than cutting new threads if all is good.

Don't recall ever having done bell housing bolts/studs, but I can't recall how many exhaust studs I've drilled out. Not rocket science - just diligence.

:thumb:

Similar threads

- Replies

- 13

- Views

- 3K

- Replies

- 0

- Views

- 499

- Replies

- 4

- Views

- 2K

New Threads

-

964 been sat for 7 years, what to do (to get it running)

- Started by DomT177

- Replies: 0

-

911uk Porsche Evening @ Fairmile Pub, Cobham, Surrey 2024 - 3rd Wed 6pm (Apr to Sept)

- Started by 911UK

- Replies: 0

-

Help regarding VTS Vodafone (Cobra) Tracker on 997.2GT3RS

- Started by Nethermill

- Replies: 4

-

An ode to the 996 c2022, aircooled evangelists find a safe space

- Started by Thunderace

- Replies: 5

-

-

-

For Sale Ed Guard Seat Bolster protectors

- Started by Darbo

- Replies: 0

Porsche Model Range

Porsche 911

Porsche 992: 2018- Porsche 991: 2011-2019

Porsche 991: 2011-2019

Porsche 997: 2004-2012

Porsche 997: 2004-2012

Porsche 996: 1997-2005

Porsche 996: 1997-2005

Porsche 993: 1993-1998

Porsche 993: 1993-1998

Porsche 964: 1989-1993

Porsche 964: 1989-1993

Porsche Carrera 3.2: 1983-1989

Porsche Carrera 3.2: 1983-1989

Porsche Carrera SC: 1977-1983

Porsche Carrera SC: 1977-1983

Porsche 930 Turbo: 1975-1989

Porsche 930 Turbo: 1975-1989

Porsche Early 911: 1964-1977

Porsche Early 911: 1964-1977

Porsche Hypercars

Porsche 918 Spyder Porsche Carrera GT

Porsche Carrera GT

Porsche GT1

Porsche GT1

Porsche 959

Porsche 959

Other Current Porsche Model

Porsche Taycan : (2019-0%) Porsche Macan : 2013-

Porsche Macan : 2013-

Porsche Panamera : 2009-

Porsche Panamera : 2009-

Porsche Cayman: 2005-

Porsche Cayman: 2005-

Porsche Cayenne: 2003-

Porsche Cayenne: 2003-

Porsche Boxster: 1997-

Porsche Boxster: 1997-

Porsche Legacy Models

Porsche 928 Porsche 968

Porsche 968

Porsche 944

Porsche 944

Porsche 924

Porsche 924

Porsche 914

Porsche 914

Porsche 912

Porsche 912

Porsche 904

Porsche 904

Porsche 550

Porsche 550

Porsche 356 Speedster

Porsche 356 Speedster

Porsche 356

Porsche 356